Why used bulk containers are reliable for large-scale material management

How Bulk Containers Can Improve Effectiveness in Your Packaging Operations

Mass containers play an important duty in enhancing packaging operations. Their layout enables much better use vertical area and promotes organized supply administration. This efficiency causes reduced material replenishment regularity and reduced labor expenses. Furthermore, the durability of these containers decreases item damage. As services seek methods to enhance their processes, understanding the diverse advantages of bulk containers ends up being essential. What other advantages might they bring to the table?

Structured Storage Solutions

As firms look for to maximize their procedures, structured storage space solutions have ended up being vital for boosting packaging effectiveness. Efficient storage not just saves room but also promotes quicker accessibility to materials, which is important in fast-paced production settings. Bulk containers, designed for easy stacking and company, considerably reduce the complexity of storage space systems. They permit services to make best use of vertical area while reducing the impact required for stock.

In addition, these containers usually feature ergonomic designs that streamline dealing with and transport, reducing the risk of injury and improving process. By combining products in bulk containers, firms can decrease the frequency of restocking and streamline their supply chain processes. Generally, the implementation of efficient storage remedies fosters an extra orderly office, causing boosted performance and reduced operational expenses. With thoughtful design and critical use of bulk containers, organizations can accomplish significant renovations in their product packaging procedures.

Waste Decrease and Sustainability

While the quest of effectiveness often drives product packaging choices, waste decrease and sustainability have emerged as important factors to consider in contemporary operations. Business increasingly acknowledge that embracing bulk containers can considerably reduce product waste. These containers frequently make use of much less packaging material than standard methods, resulting in a smaller sized carbon impact.

Moreover, bulk containers can be reused multiple times, which better lowers the need for single-use packaging and minimizes overall waste getting in landfills. Their design commonly enables much easier recycling procedures, straightening with sustainability goals.

Furthermore, companies that prioritize waste reduction can improve their brand name credibility, interesting eco aware consumers. By executing mass containers, organizations not just improve procedures but also contribute positively to ecological stewardship. This twin benefit of functional performance and sustainability placements business favorably in an open market progressively focused on green methods.

Boosted Production Line Efficiency

Carrying out mass containers on setting up lines greatly improves performance by simplifying the handling and transport of materials. By utilizing bulk containers, suppliers can minimize the frequency of product replenishment, allowing employees to concentrate on setting up tasks as opposed to continuous supply monitoring. This results in less interruptions and a smoother process, inevitably improving efficiency.

In addition, bulk containers are developed for very easy combination with automated systems, even more maximizing the setting up procedure. Their standard sizes and shapes help with much better organization, allowing workers to situate and access products swiftly. This reduction in search time adds to a more fluid production atmosphere.

Price Savings and Enhanced Revenue Margins

Noteworthy cost savings can be recognized via the adoption of mass containers in product packaging procedures. By lowering the need for several smaller sized packages, business can lower product costs significantly. Bulk containers usually call for less packaging material on the whole, leading to lower expenditures on supplies. Additionally, the effectiveness of bulk handling reduces labor costs connected with packaging and unpacking, better improving savings.

Fewer trips to providers and decreased transportation costs are additionally crucial benefits, as bulk containers enable boosted product capacity per shipment. This higher quantity not only lowers delivery expenditures yet also maximizes storage space within facilities, bring about enhanced stock administration.

Additionally, the durability of mass containers commonly converts to reduce damage prices during handling and transport, protecting product stability and reducing waste. Collectively, these elements add to better profit margins, making bulk containers an economically advantageous selection for companies looking for effectiveness in their product packaging procedures.

Flexibility Throughout Industries

Bulk containers supply amazing convenience throughout various industries, making them a valuable asset past just set you back savings. In the food and drink field, these containers assist in the safe transportation and storage space of huge quantities of active ingredients, enhancing performance in assembly line. In drugs, bulk containers guarantee conformity with stringent hygiene requirements while suiting the mass handling of resources. The chemical industry likewise advantages, as these containers endure severe compounds and stop contamination, supporting secure procedures. used collapsible containers. In addition, the agricultural sector uses bulk containers for delivering plant foods and grains, enhancing logistics and lowering waste. Their adaptability expands to manufacturing, where mass containers enhance setting up procedures and lower the need for excessive packaging. This cross-industry capability not just improves functional efficiency however likewise advertises sustainability through reduced packaging waste, highlighting the indispensable role bulk containers play in contemporary supply chains

Regularly Asked Inquiries

How Do Bulk Containers Impact Staff Member Safety And Security in Product Packaging Workflow?

Bulk containers substantially enhance worker security in packaging procedures by decreasing manual handling, minimizing injury threats, and advertising ergonomic practices. Their layout promotes safer transportation and storage space, ultimately producing an extra safe job environment for all employees.

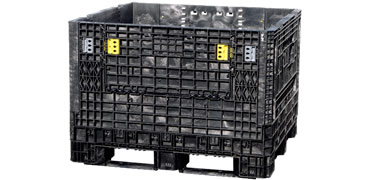

What Products Are Mass Containers Normally Made From?

Bulk containers are commonly made from durable products such as high-density polyethylene, metal, wood, or polypropylene - used bulk containers. These materials give stamina, resistance to ecological factors, and viability for numerous contents, ensuring effective and secure transport of goods

Can Mass Containers Be Custom-made for Specific Products?

Yes, bulk containers can be personalized for certain products. Suppliers usually customize dimensions, materials, and features to fulfill distinct needs, ensuring perfect security and efficiency throughout storage space and transport of numerous items.

Exactly How Do Mass Containers Affect Transportation Logistics?

Bulk containers improve transportation logistics by taking full advantage of cargo area, minimizing the variety of trips needed, and lessening dealing with costs (used plastic containers). Their standard measurements promote efficient dumping and filling, inevitably leading to boosted operational effectiveness throughout the supply chain

What Is the Life Expectancy of Mass Containers in Regular Usage?

The life expectancy of mass containers in routine usage usually varies from 5 to 10 years, relying on material high quality, dealing with practices, and environmental problems. Appropriate upkeep can greatly extend their usability and efficiency.

Applying mass containers read more on assembly lines substantially boosts performance by streamlining the handling and transportation of materials. Mass containers commonly require much less product packaging material in general, resulting in lower expenditures on supplies. In drugs, mass containers ensure conformity with rigid hygiene criteria while fitting the bulk handling of raw products. Their versatility expands to manufacturing, where mass containers streamline assembly processes and reduce the need for too much product packaging. Bulk containers substantially improve employee security in product packaging procedures by decreasing hand-operated handling, minimizing injury dangers, and advertising ergonomic practices.